| Availability: | |

|---|---|

H013~H300

Nuochen

Introduction

Stainless Steel PHE Copper Beer To Water Brazed Plate Heat Exchanger

Benefits

• Small and Compact

• Easy to install

• Self-cleaning

• All are pressure and leak tested

• Gasket free

•Wort Chiller titanium Brazed Plate Heat Exchanger

Design

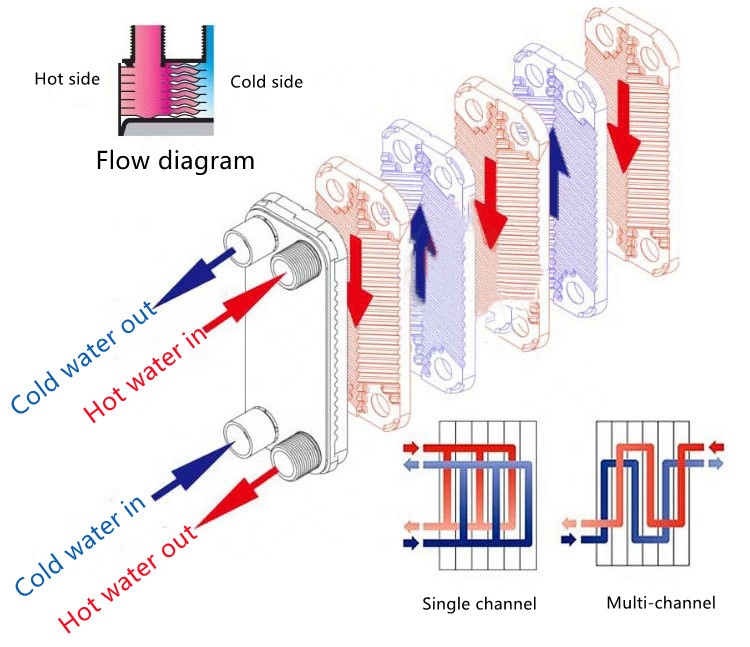

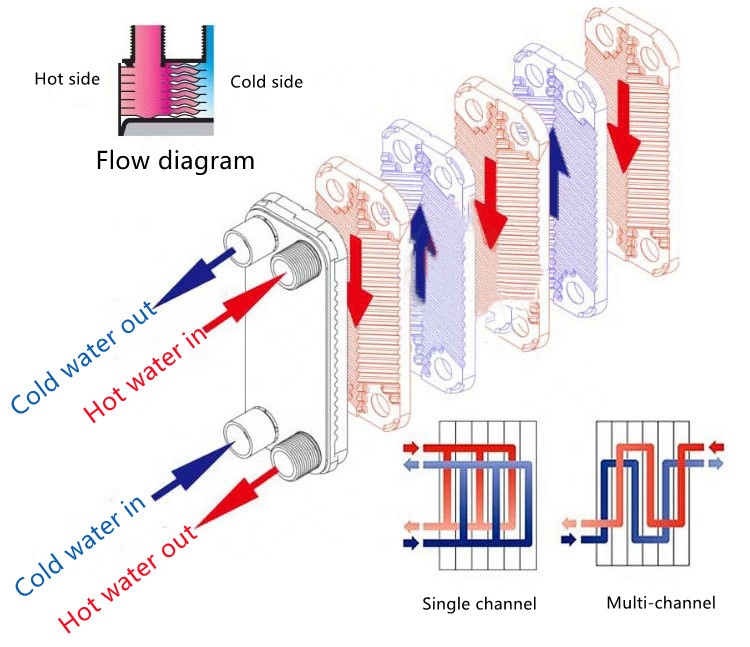

Brazing material seals and holds the plates together at the contact points ensuring optimal heat transfer efficiency and pressure resistance.

Using advanced design technologies and extensive verification guarantees the highest performance and longest possible service life.

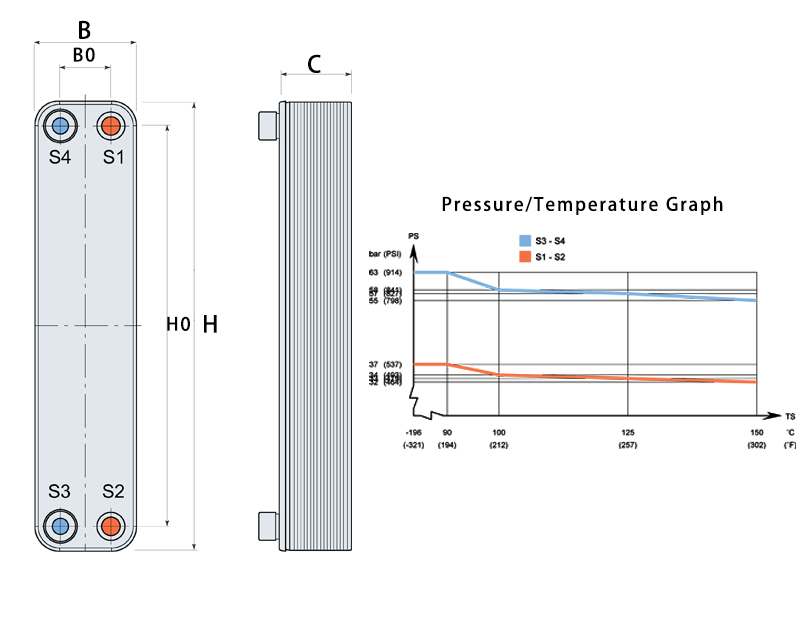

Different pressure ratings are available for different needs.

The unit can be supplied with a refrigerant distribution system for optimal evaporator performance.

liquid 20kw Brazed Plate Heat Exchanger

Based on standard components and a modular concept, each unit is custom-built to meet the specific requirements of each individual installation.

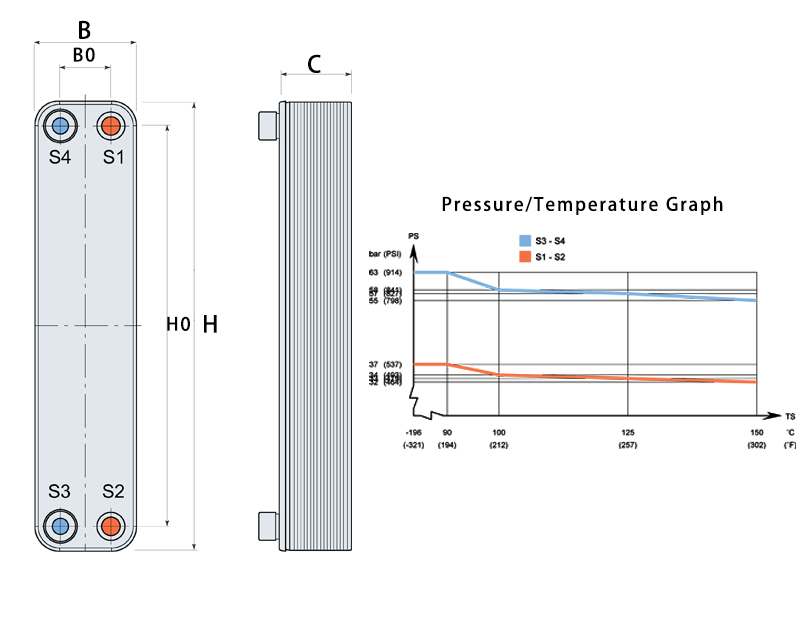

| Model | High H | Width B | Thickness C | Longitudinal Hole Distance H0 | Horizontal Hole Distance B0 | Weight kg | Unilateral Stagnation Valume(L) | Heat Exchanger Area m2 |

| H013 | 192 | 78 | 2.3*N+9 | 152 | 40 | 0.04*N+0.4 | (N-2)*0.008 | (N-2)*0.013 |

| H014 | 208 | 76 | 2.3*N+9 | 168 | 42 | 0.05*N+0.5 | (N-2)*0.01 | (N-2)*0.014 |

| H015 | 200 | 90 | 2.1*N+9 | 160 | 46 | 0.05*N+0.4 | (N-2)*0.011 | (N-2)*0.015 |

| H016 | 200 | 90 | 3.1*N+9 | 160 | 46 | 0.05*N+0.5 | (N-2)*0.014 | (N-2)*0.016 |

| H020 | 310 | 76 | 2.3*N+9 | 282 | 42 | 0.058*N+1 | (N-2)*0.018 | (N-2)*0.02 |

| H026 | 310 | 111 | 2.4*N+9 | 250 | 50 | 0.11*N+1 | (N-2)*0.025 | (N-2)*0.026 |

| H030 | 325 | 95 | 1.55*N+9 | 269 | 39 | 0.09*N+1 | (N-2)*0.03 | (N-2)*0.03 |

| H050 | 525 | 111 | 2.4*N+9 | 466 | 50 | 0.2*N+2.4 | (N-2)*0.05 | (N-2)*0.05 |

| H060 | 527 | 120 | 2.3*N+9 | 479 | 72 | 0.19*N+2.4 | (N-2)*0.11 | (N-2)*0.06 |

| H095A | 616 | 191 | 2.45*N+11 | 519 | 92 | 0.36*N+7.8 | (N-2)*0.1 | (N-2)*0.095 |

| H095B | 616 | 191 | 2.8*N+11 | 519 | 92 | 0.44*N+7.8 | (N-2)*0.12 | (N-2)*0.095 |

| H095C | 616 | 191 | 2.8*N+11 | 519 | 92 | 0.44*N+7.8 | (N-2)*0.12 | (N-2)*0.095 |

| H100 | 490 | 250 | 2.8*N+11 | 391 | 157 | 0.35*N+6.5 | (N-2)*0.08 | (N-2)*0.1 |

| H110 | 528 | 246 | 2.4*N+12 | 456 | 174 | 0.52*N+6.5 | (N-2)*0.19 | (N-2)*0.11 |

| H190 | 698 | 307 | 2.65*N+13 | 567 | 179 | 0.51*N+10 | (N-2)*0.21 | (N-2)*0.19 |

| H210 | 739 | 322 | 2.55*N+13 | 599 | 211 | 0.82*N+13 | (N-2)*0.2 | (N-2)*0.21 |

| H220 | 734 | 319 | 2.65*N+13 | 622 | 205 | 0.7*N+13 | (N-2)*0.22 | (N-2)*0.22 |

| H300 | 1006 | 366 | 2.8*N+16 | 872 | 228 | 1.26*N+57 | (N-2)*0.35 | (N-2)*0.3 |

Introduction

Stainless Steel PHE Copper Beer To Water Brazed Plate Heat Exchanger

Benefits

• Small and Compact

• Easy to install

• Self-cleaning

• All are pressure and leak tested

• Gasket free

•Wort Chiller titanium Brazed Plate Heat Exchanger

Design

Brazing material seals and holds the plates together at the contact points ensuring optimal heat transfer efficiency and pressure resistance.

Using advanced design technologies and extensive verification guarantees the highest performance and longest possible service life.

Different pressure ratings are available for different needs.

The unit can be supplied with a refrigerant distribution system for optimal evaporator performance.

liquid 20kw Brazed Plate Heat Exchanger

Based on standard components and a modular concept, each unit is custom-built to meet the specific requirements of each individual installation.

| Model | High H | Width B | Thickness C | Longitudinal Hole Distance H0 | Horizontal Hole Distance B0 | Weight kg | Unilateral Stagnation Valume(L) | Heat Exchanger Area m2 |

| H013 | 192 | 78 | 2.3*N+9 | 152 | 40 | 0.04*N+0.4 | (N-2)*0.008 | (N-2)*0.013 |

| H014 | 208 | 76 | 2.3*N+9 | 168 | 42 | 0.05*N+0.5 | (N-2)*0.01 | (N-2)*0.014 |

| H015 | 200 | 90 | 2.1*N+9 | 160 | 46 | 0.05*N+0.4 | (N-2)*0.011 | (N-2)*0.015 |

| H016 | 200 | 90 | 3.1*N+9 | 160 | 46 | 0.05*N+0.5 | (N-2)*0.014 | (N-2)*0.016 |

| H020 | 310 | 76 | 2.3*N+9 | 282 | 42 | 0.058*N+1 | (N-2)*0.018 | (N-2)*0.02 |

| H026 | 310 | 111 | 2.4*N+9 | 250 | 50 | 0.11*N+1 | (N-2)*0.025 | (N-2)*0.026 |

| H030 | 325 | 95 | 1.55*N+9 | 269 | 39 | 0.09*N+1 | (N-2)*0.03 | (N-2)*0.03 |

| H050 | 525 | 111 | 2.4*N+9 | 466 | 50 | 0.2*N+2.4 | (N-2)*0.05 | (N-2)*0.05 |

| H060 | 527 | 120 | 2.3*N+9 | 479 | 72 | 0.19*N+2.4 | (N-2)*0.11 | (N-2)*0.06 |

| H095A | 616 | 191 | 2.45*N+11 | 519 | 92 | 0.36*N+7.8 | (N-2)*0.1 | (N-2)*0.095 |

| H095B | 616 | 191 | 2.8*N+11 | 519 | 92 | 0.44*N+7.8 | (N-2)*0.12 | (N-2)*0.095 |

| H095C | 616 | 191 | 2.8*N+11 | 519 | 92 | 0.44*N+7.8 | (N-2)*0.12 | (N-2)*0.095 |

| H100 | 490 | 250 | 2.8*N+11 | 391 | 157 | 0.35*N+6.5 | (N-2)*0.08 | (N-2)*0.1 |

| H110 | 528 | 246 | 2.4*N+12 | 456 | 174 | 0.52*N+6.5 | (N-2)*0.19 | (N-2)*0.11 |

| H190 | 698 | 307 | 2.65*N+13 | 567 | 179 | 0.51*N+10 | (N-2)*0.21 | (N-2)*0.19 |

| H210 | 739 | 322 | 2.55*N+13 | 599 | 211 | 0.82*N+13 | (N-2)*0.2 | (N-2)*0.21 |

| H220 | 734 | 319 | 2.65*N+13 | 622 | 205 | 0.7*N+13 | (N-2)*0.22 | (N-2)*0.22 |

| H300 | 1006 | 366 | 2.8*N+16 | 872 | 228 | 1.26*N+57 | (N-2)*0.35 | (N-2)*0.3 |