| Availability: | |

|---|---|

Customized

Nuochen

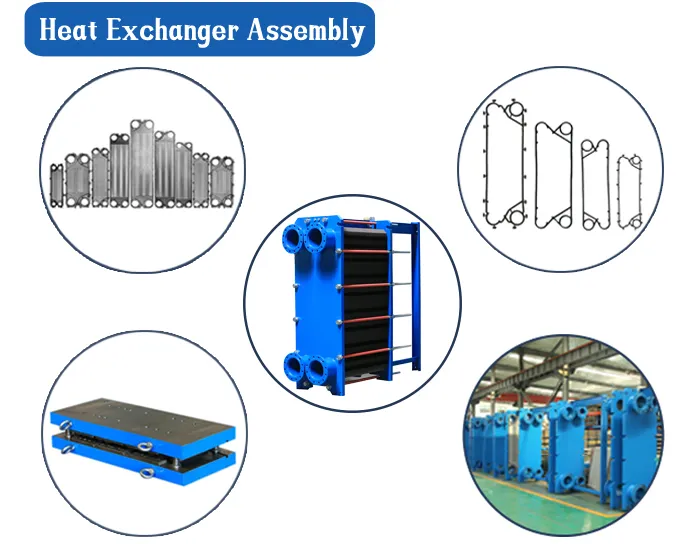

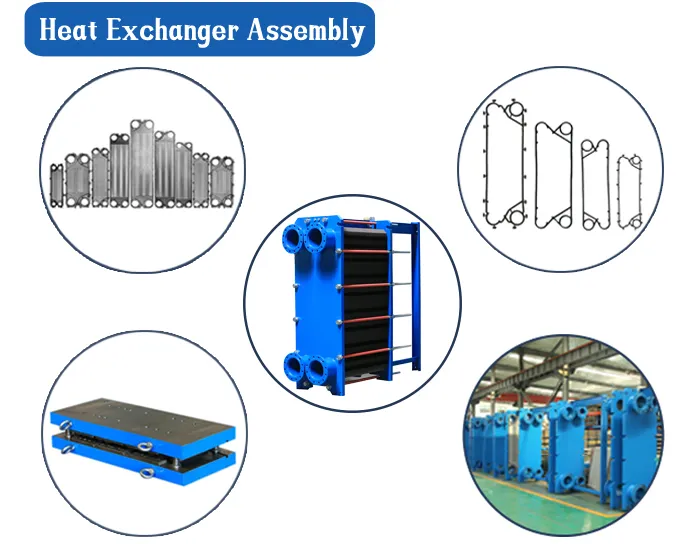

Gasket Plate Marine Heat Exchanger Beer Plate Heat Exchanger for Fermentation with Competitive Price

Commonly used categories are:

1 According to the amount of heat exchange area in the unit space, the plate heat exchanger is a compact heat exchanger, mainly compared with the shell and tube heat exchanger, the traditional shell and tube heat exchanger occupies a larger area.

2 According to the process use, there are different names: plate heater, plate cooler, plate condenser, plate preheater;

3 According to the process combination, it is divided into single-pass plate heat exchanger and multi-pass plate heat exchanger;

4 According to the flow direction of the two media, it is divided into co-current (co-current) plate heat exchangers, counter-flow plate heat exchangers, and cross-flow (cross-flow) plate heat exchangers, the latter two are used more often;

5 According to the gap size of the flow channel, it is divided into conventional gap plate heat exchanger and wide gap plate heat exchanger;

6 According to the corrugation, the plate heat exchanger has a more detailed distinction, which will not be repeated, please refer to: plate heat exchanger plate corrugation form.

7 According to whether it is a complete set of products, it can be divided into stand-alone plate heat exchangers and plate heat exchanger units

Gasket Plate Marine Heat Exchanger Beer Plate Heat Exchanger for Fermentation with Competitive Price

Commonly used categories are:

1 According to the amount of heat exchange area in the unit space, the plate heat exchanger is a compact heat exchanger, mainly compared with the shell and tube heat exchanger, the traditional shell and tube heat exchanger occupies a larger area.

2 According to the process use, there are different names: plate heater, plate cooler, plate condenser, plate preheater;

3 According to the process combination, it is divided into single-pass plate heat exchanger and multi-pass plate heat exchanger;

4 According to the flow direction of the two media, it is divided into co-current (co-current) plate heat exchangers, counter-flow plate heat exchangers, and cross-flow (cross-flow) plate heat exchangers, the latter two are used more often;

5 According to the gap size of the flow channel, it is divided into conventional gap plate heat exchanger and wide gap plate heat exchanger;

6 According to the corrugation, the plate heat exchanger has a more detailed distinction, which will not be repeated, please refer to: plate heat exchanger plate corrugation form.

7 According to whether it is a complete set of products, it can be divided into stand-alone plate heat exchangers and plate heat exchanger units